Global Energy Solution

SEG offers a global solution that can harness economically clean, sustainable, and unlimited renewable energy.

Clean Energy Generation

The most advanced energy solution by way of the electron's inherent kinetic energy; this means NO wood, NO coal, NO gas, NO radiation, NO wear, NO heating, NO noise, and NO environmental problems.

Become a SEGS Member

All membership contributions from the same Member will add up over any period of time, and that can take your membership up to the highest level – Group Funding.

SEG Society

Welcome to the SEG Society, where Membership supports SEG development and paves the way to a bright future for Mankind. This is the starting point for the SEG organization's future success. As a member of the Society, you can support the development of the SEG.

What is the Searl Effect Generator (Seg)?

The SEG can be as small as one meter in diameter and can generate 15 kWh and provide power to any AC/DC device.

It requires no other source of fuel other than free-floating electrons, which exist everywhere in nature.

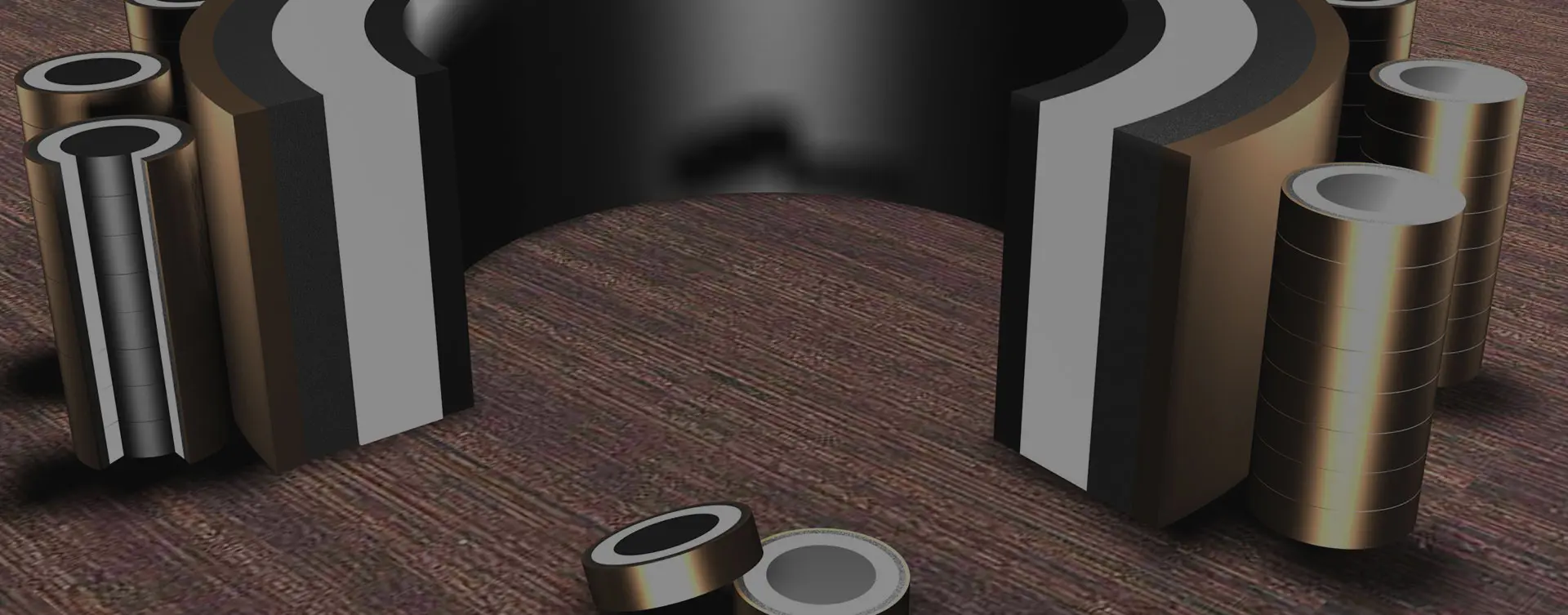

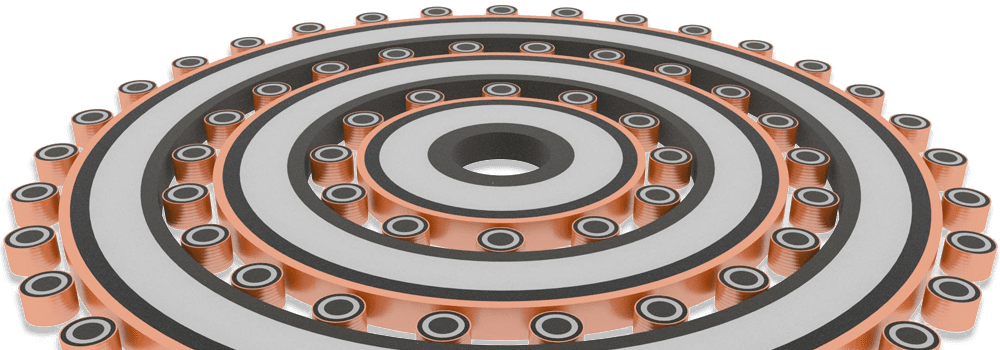

Technology Physical Configuration

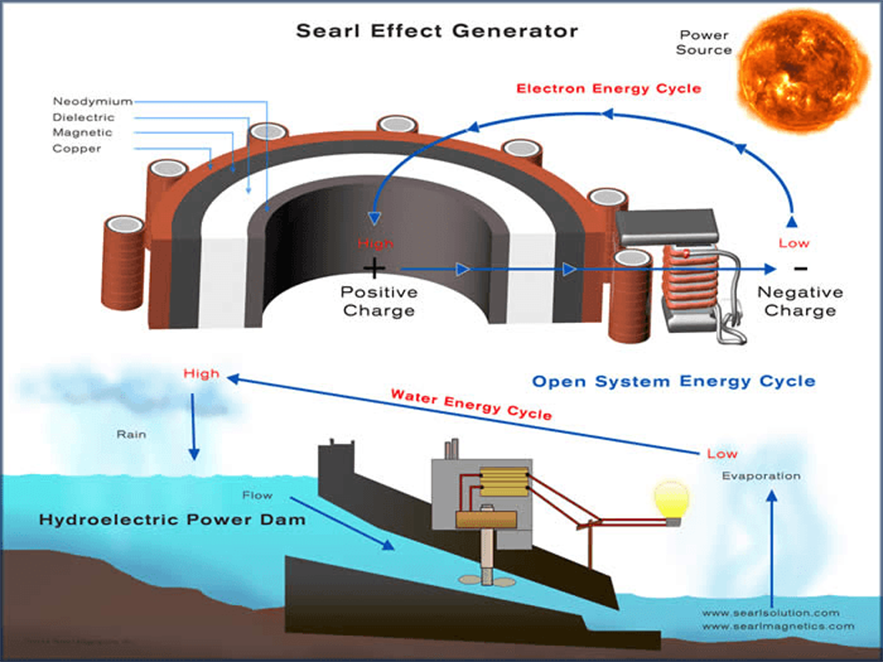

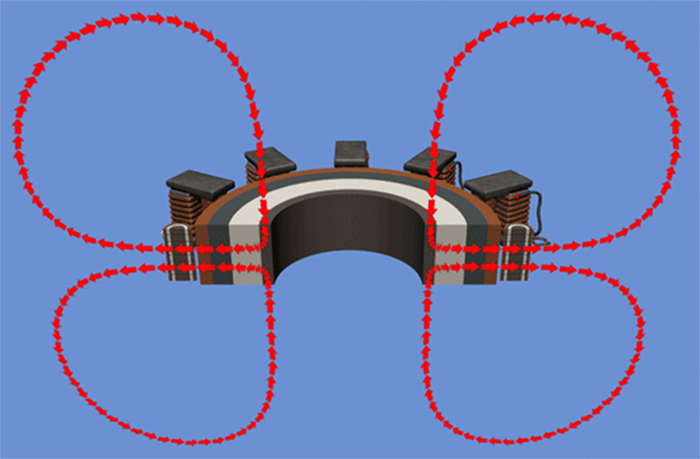

The SEG consists of three Stator Rings that are composed of four distinctively different materials concentrically layered to each other and fixed to a base. Surrounding each of the Plates are rotors (called Rollers) constructed with the same materials but are free to rotate around the Stator Ring. The innermost Stator Ring has 12 rollers, 22 on the second stage, and 32 on the final Stator Ring. Conventional electromagnets surround the outermost set of Rollers. They are C-shaped cores, and by way of magnetic induction, they tap energy out of the rapidly orbiting Rollers. These inductive pickup coils are connected in various configurations to supply AC or DC power at a variety of desired voltage and current levels to suit residential, business, or industrial applications. The SEG is defined as a device constructed of 2,124 parts that make up 3 Stator rings (12 parts) and 66 Roller sets (2112). Each roller set consists of 8 segments constructed from 32 component parts. Each set of Stator Rings and Rollers is configured to power out in series from the innermost to the outside, and each has ratings based on its mass or weight. The rule of thumb is 90 watts per pound or 200 watts per kilogram of the generator's weight. It follows that the first stage or innermost is rated at 2.5 kW, the second stage at 4.5 kW, and the outermost rates at 8 kW for a 15 kW SEG unit. Therefore, the smallest unit is the innermost and is suitable for the smallest power requirements.

How does it work?

The best way to describe how the SEG works is to compare it to a concept we already understand fully: a Dam.

Current Progress and Development

The SEG is a concept under development in San Diego County, California, USA. SEG Magnetics, Inc. (SEGM) has investigated the concept extensively within modest budgets. It has been an active R&D project since June 2010. The results are very encouraging and confirm our understanding of the SEG functions and capabilities. Much of it is now self-evident with the proof-of-concept demonstration units, and more units are scheduled with additional time and resources. Now, our objective is to speed up and finalize the development of SEG with complete funding of the project and to proceed with any production plans.